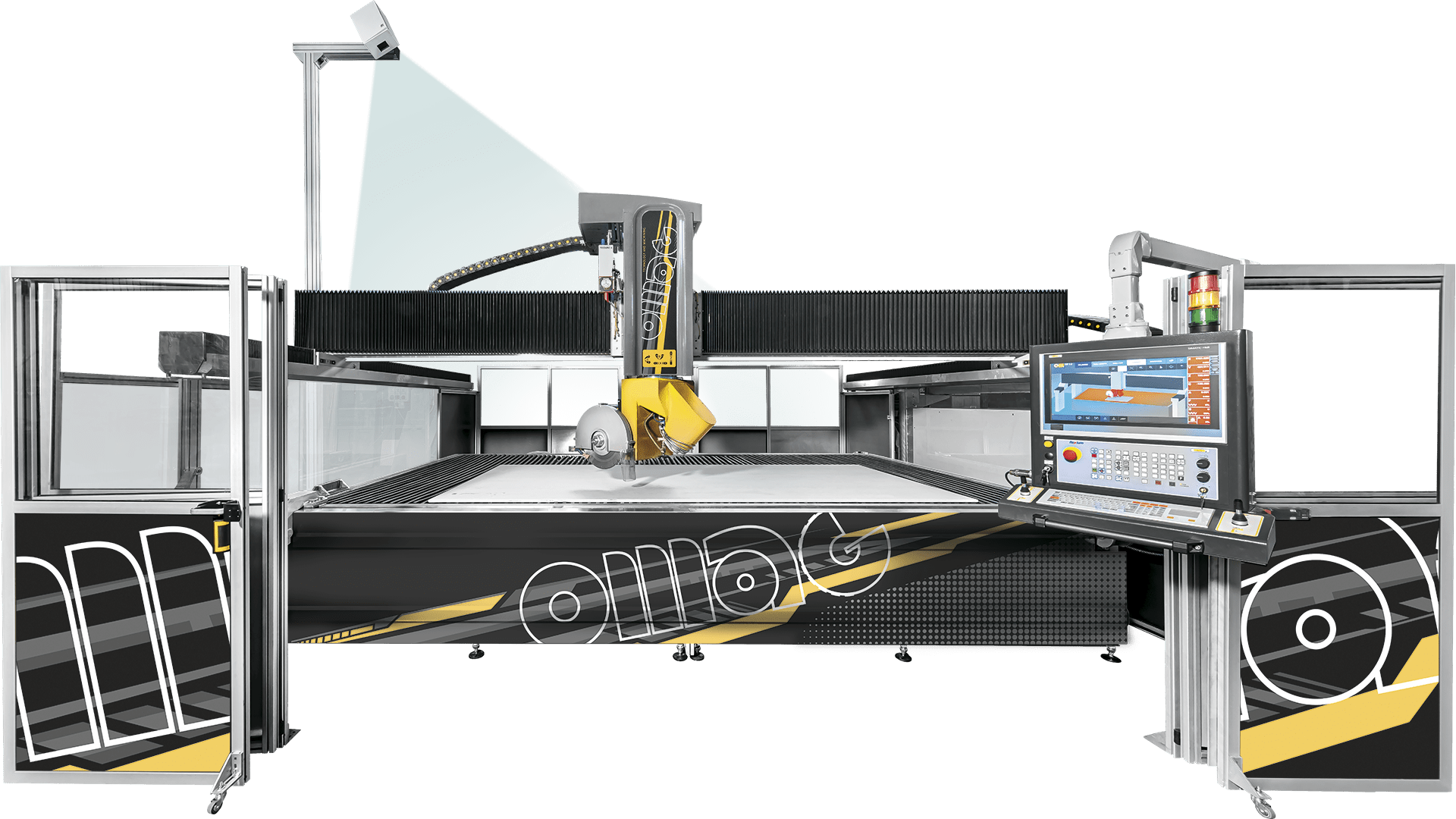

The use of technological materials entails the need to use cutting systems with high pressure water, in order to ensure high quality cutting, with production costs significantly higher than cutting on disk. Considering that the disc manufacturers are increasingly developing products capable of cutting technological materials with an excellent degree of quality; considering that cutting with a disc is always faster than water and has a lower cost. The combination of the two systems, cutting with high pressure water and cutting with disc, is an excellent combination that fully satisfies quality, production costs and low working times.

The Water Jet is the cold cutting solution, suitable for pieces shaped with more or less complex geometries up to thicknesses quite significant. A water jet can be used pure or mixed with abrasive. The cutting unit is mounted on edge of the axis slide (Z) and is composed of a cutting kit which provides for the mixing of water and abrasive. The heads for cutting water jet used by OMAG guarantee the maximum efficiency and minimal maintenance.

Video

| Controlled and interpolated axes n° | 5 |

| Size of the slab support surface | 4.000 x 2.400 mm |

| X-axis – Cross axis stroke | 4.100 mm |

| Y-axis – Bridge axis stroke | 3.050 mm |

| Z-axis – Vertical axis stroke | 400 mm |

| C-axis – Rotation on axis | ± 400° |

| A-axis – Cutting head inclination with water | ± 70° |

| X and Y axis movement speed | 42 mt/min |

| Z-axis movement speed | 15 mt/min |

| Table inclination with maximum tilting capacity ** | 80° |

| Maximum static capacity applicable on the table | 3.000 Kg |

| Maximum distance from the cutting head with water to the support surface | 150 mm |

| Diameter minimum and maximum mountable discs | Ø 300 ÷ 400 |

| Maximum cutting thickness with disc diameter Ø 300 | 71 mm |

| Disc motor power KW/HP and maximum rotation RPM | 7,5 Kw 3600 Rpm |

| Dimensions of cutting surface with “combined” disc and water cutting head | 3.800 x 2.250 mm |

| Distance from the base of the cutting disc Ø 300 to the support surface | 150 mm |