Cut

Stronger than granite

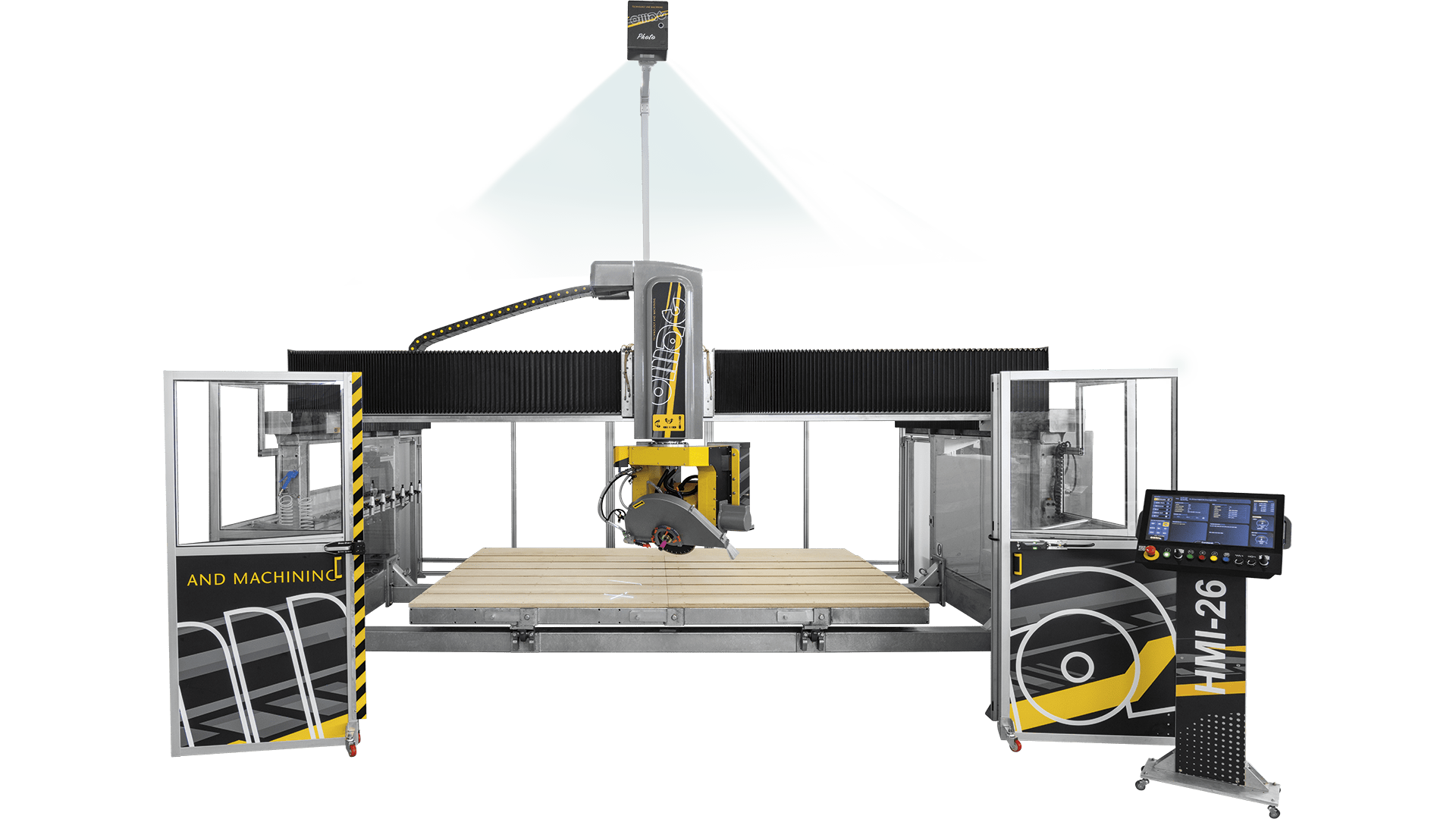

This work center has been thought for the purpose to offer in a small space, a machine capable of being able to carry out all the operations required to a laboratory both small and medium size. The high speed of movement, the accelerations of the axes are guaranteed by a digital control system.

Monoblock

NC bridge saw 5 axes with milling functions, monobloc with twist head, specially engineered to cut, drill, polishing and shape items of granite, marble, quartz, porcelain and ceramic.

Video

| Interpolated controlled axes | n° | 5 |

| Ø Maximum diameter saw | mm | 625 |

| Cutting thickness | mm | 200 |

| Ø Minimum diameter saw | mm | 350 |

| Axis X – Transversal stroke* | mm | 3.600 |

| Axis Y – Longitudinal stroke* | mm | 2.500 |

| Axis Z – Vertical stroke* | mm | 400÷700 |

| Axis C – Rotation | 0° 380° | |

| Axis B – Tilting | 0° ÷ 90° | |

| X axis movement speed | m/min | 0 ÷ 48 |

| Y axis movement speed | m/min | 0 ÷ 40 |

| Z axis movement speed | m/min | 0 ÷ 15 |

| Table sizes | mm | 3.600 x 2.000 + 500 |

| Motor power | 24,4 HP (s6) | |

| Tool Attachment** | 1/2″ GAS | |

| Rotating control by inverter | RPM | 0 ÷ 6.000 |

| Water consumption | 40 l/ min | |

| On demand | ||

| Electrospindle for incremental cutting ceramic | 3,5 HP (s6) |