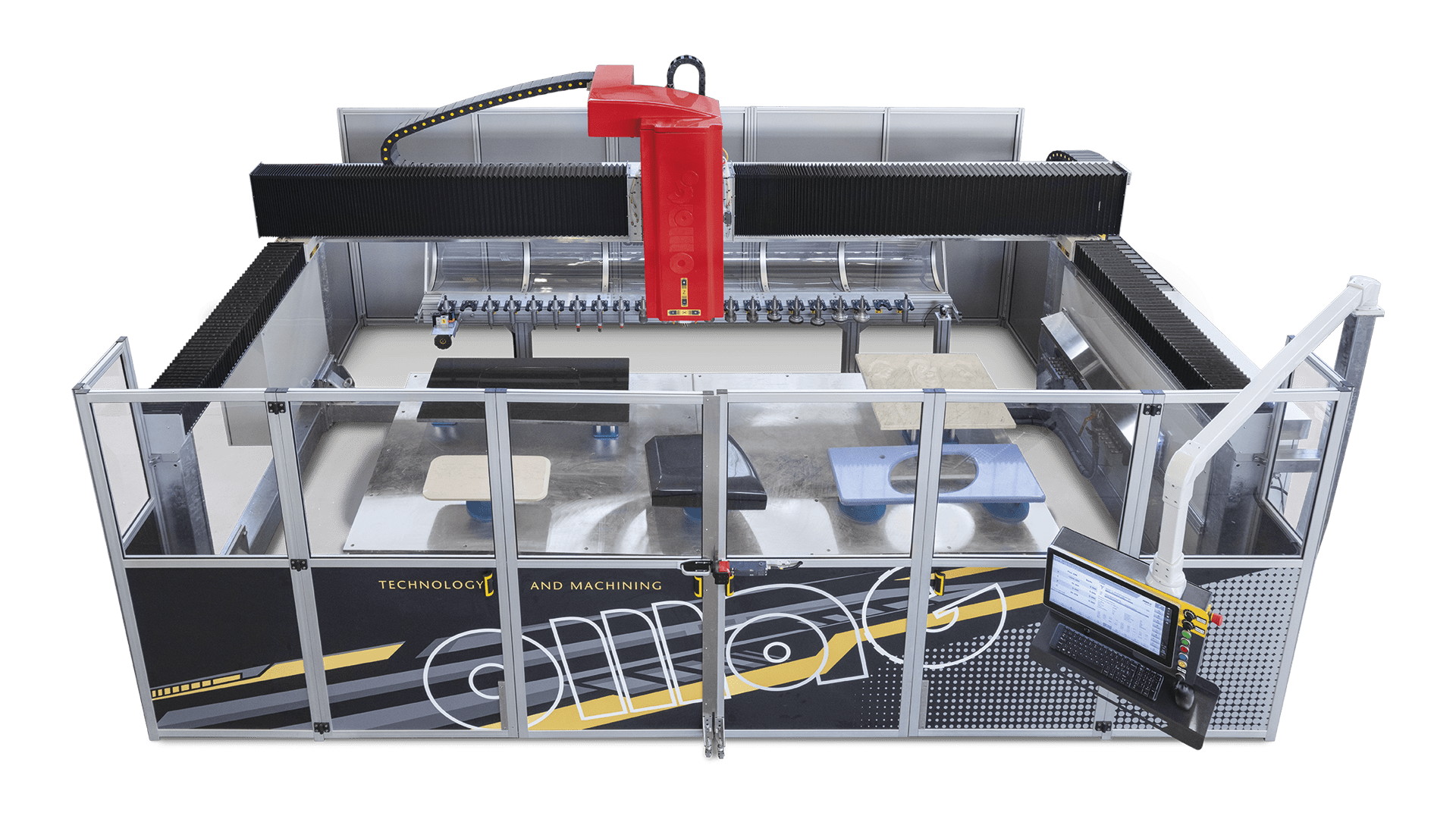

OMAG DIGIMILL and MILL4X are 4-axis numerical control machining centers, which group all the functions of a machining center in a single system multifunction. OMAG DIGIMILL and MILL4X are the result of OMAG experience gained in 40 years of production and the combination of the best technologies, with the simplicity of setting the job for shaping, contouring, engraving, milling, sculpting, polishing, of natural and synthetic materials, as well as ceramics.

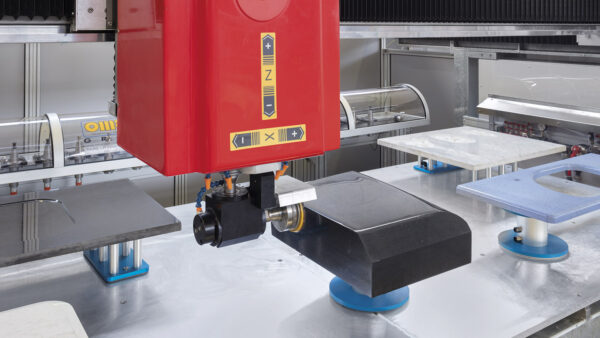

OMAG DIGIMILL and MILL4X are a highly productive machine both when mass production is required and for unique and original pieces. The high speed of the movement of the axes is ensured by a brushless motorization combined with ball screws, while the sliding on linear guides with ball runners, the protection of moving parts with pvc bellows and a centralized lubrication system guarantee quality and precision over time.

The numerical controls used are from the main world manufacturers, the software development (CAD / CAM) and the customization of the functions is guaranteed by a staff of engineers who also have the task to ensure a constant training and assistance service.

| Interpolated controlled axes | n° | 3+1 |

| Axis X – Transversal stroke | mm | 3.600 |

| Axis Y – Longitudinal stroke | mm | 1.500 |

| Axis Z – Vertical stroke | mm | 350 |

| Axis C – Rotation | Unlimited / Illimitata | |

| X axis movement speed | m/min | 0 ÷ 48 |

| Y axis movement speed | m/min | 0 ÷ 40 |

| Z axis movement speed | m/min | 0 ÷ 15 |

| < T > axis inclination, lowered plane | .+0.28° -0.28° | |

| Ø Disc maximum diameter (on ISO angular head) | mm | Ø 200 |

| Table sizes | mm | 3.600 x 1.500 |

| Tool magazine | n° | 22 |

| Motor power | 15 HP (s6) | |

| Tool Attachment | ISO40 | |

| Rotating control by inverter | RPM | 0 ÷ 10.000 |

| Water consumption | l/min | 25 |