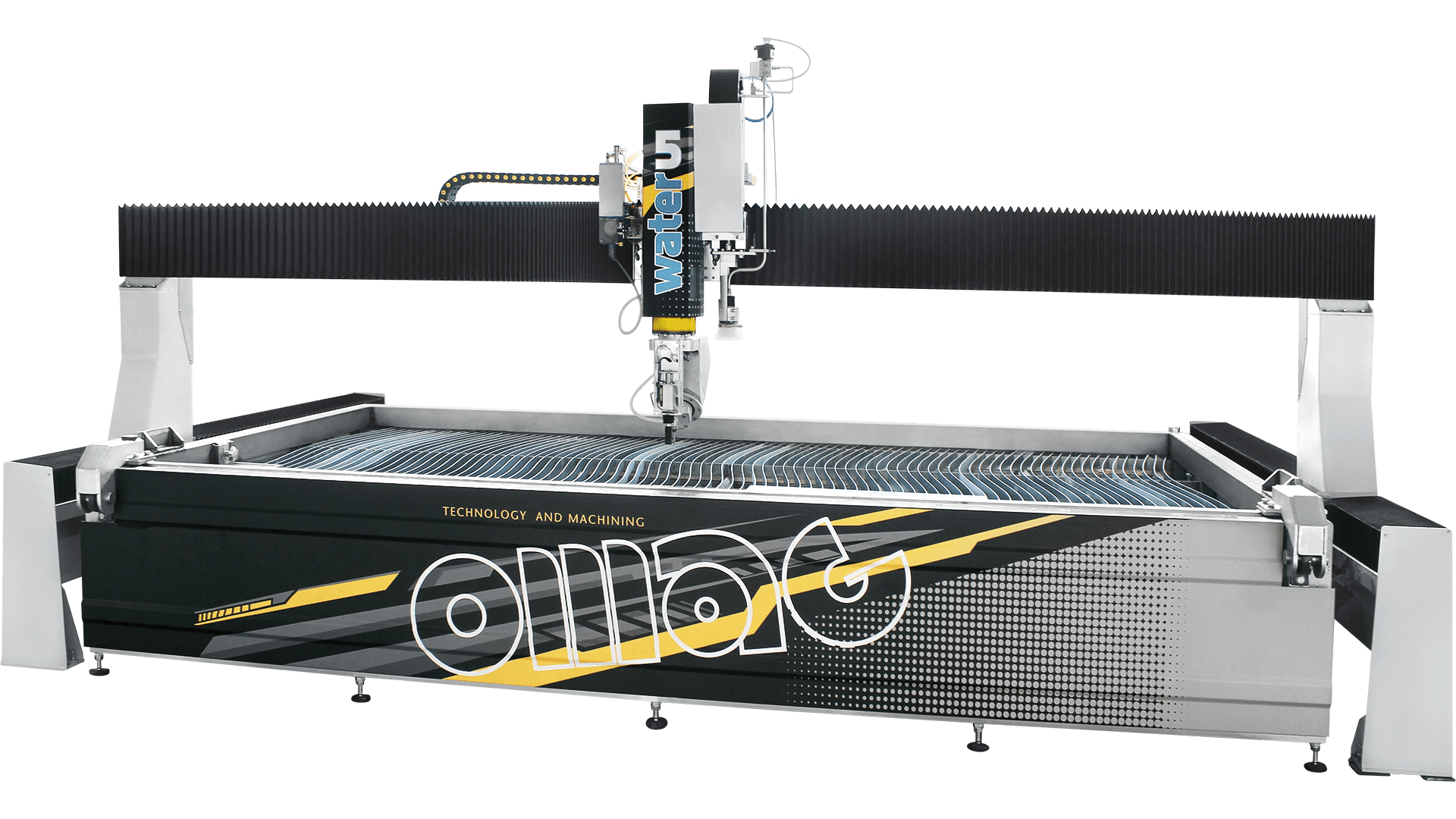

Cut

Cold cutting solution for shaped pieces

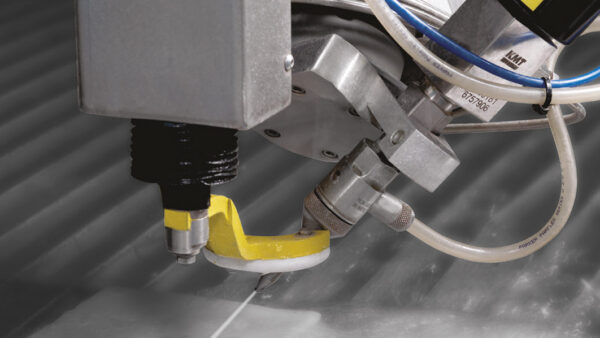

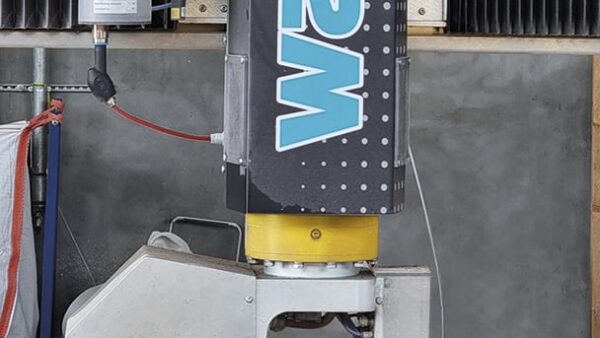

The Water Jet is the cold cutting solution for shaped pieces with more or less complex geometries up to quite relevant thicknesses. A pure water or mixed with abrasive jet can be used . The X and Y axes are motorized with a brushless digital system with helical hardened pinions and racks. The linear ball guides guarantee further handling quality. The Z axis is equipped with a ball screw.

Video

| Controlled and interpolated axes n° | 5 |

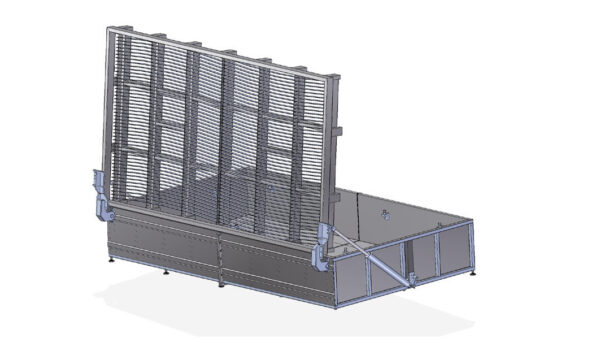

| Size of the slab support surface | 4.000 x 2.000 mm |

| X-axis – Cross axis stroke | 4.000 mm |

| Y-axis – Bridge axis stroke | 2.000 mm |

| Z-axis – Vertical axis stroke | 200 mm |

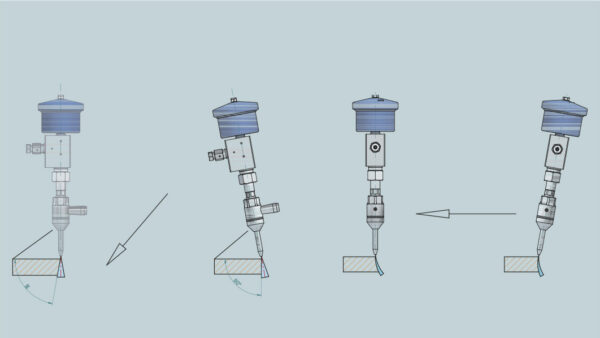

| C-axis – Rotation on axis | ± 400° |

| A-axis – Cutting head inclination with water | ± 70° |

| X and Y axis movement speed | 42 mt/min |

| Z-axis movement speed | 15 mt/min |

| Table inclination with maximum tilting capacity ** | 80° |

| Maximum static capacity applicable on the table | 3.000 Kg |

| Maximum distance from the cutting head with water to the support surface | 150 mm |

| Diameter minimum and maximum mountable discs | – |

| Maximum cutting thickness with disc diameter Ø 300 | – |

| Disc motor power KW/HP and maximum rotation RPM | – |

| Dimensions of cutting surface with “combined” disc and water cutting head | – |

| Distance from the base of the cutting disc Ø 300 to the support surface | – |