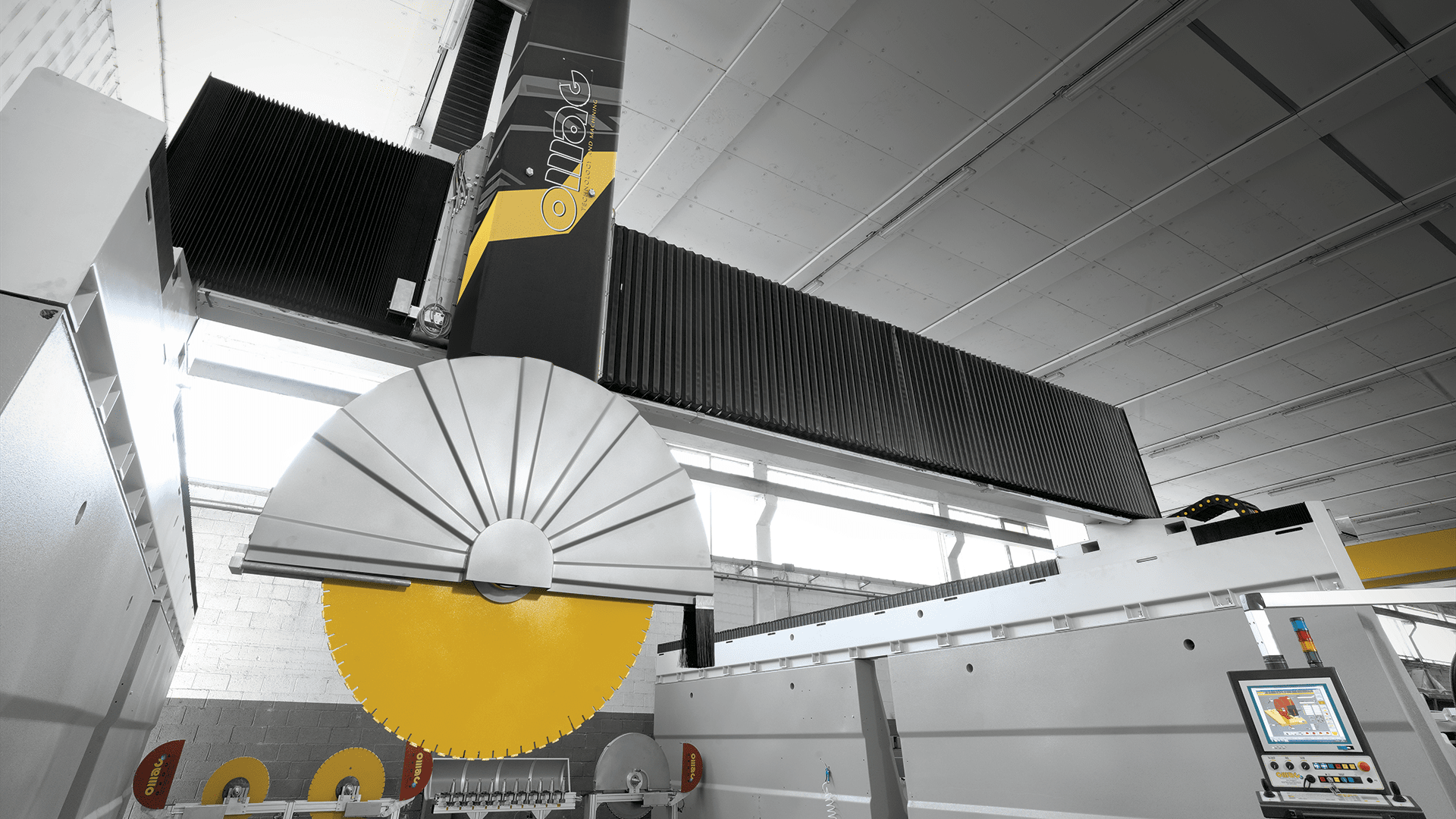

CNC Working Center

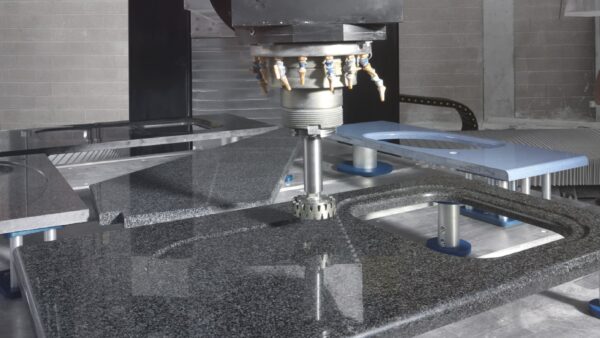

A BLADE machine means uniquely technology, precision and reliability. A numerical control working center projected to work with large saws and milling tools of all the measures, marble, stone or granite.

The high speed of the movement of the axes is guaranteed by a full digital brushless motorization combined with a sliding movement on linear guides rails and ball bearing blocks. All the moving parts are protected by PVC bellows and a centralized lubrication system grant quality and durability in long time.

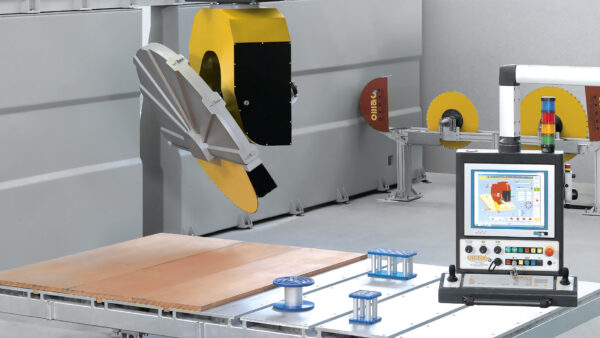

OMAG machines are equipped with Easy and Fast System Process Controls providing state-of-the-art process control in a user-friendly environment. Easy and Fast System Process Controls consistently monitor and control all variables in real time against your pre-established programmed. A monitoring for cutting and milling increases work performance and resulting in patterns highest quality.

| Interpolated controlled axes | n° | 5 |

| Ø Maximum diameter saw | mm | 1.600 |

| Cutting thickness | mm | 600 |

| Ø Minimum diameter saw | mm | 625 |

| Axis X – Transversal stroke* | mm | 4.000 |

| Axis Y – Longitudinal stroke* | mm | 3.000 |

| Axis Z – Vertical stroke* | mm | 1.000 ÷ 2.000 |

| Axis C – Rotation | 0° 380° | |

| Axis B – Tilting | 0° ÷ +/- 140° | |

| Table sizes | mm | 4.000 x 2.500 |

| ISO Automatic Blade Change | mm | Ø 625 |

| ISO Automatic Blade Change | mm | Ø 850 |

| ISO Automatic Blade Change | mm | Ø 1200 |

| Motor power | 76 HP (s6) | |

| Tool Attachment | ISO50 | |

| Rotating control by inverter | RPM | 0 ÷ 8.000 |

| Water consumption | l/ min | 60 |