OMAG Made to measure

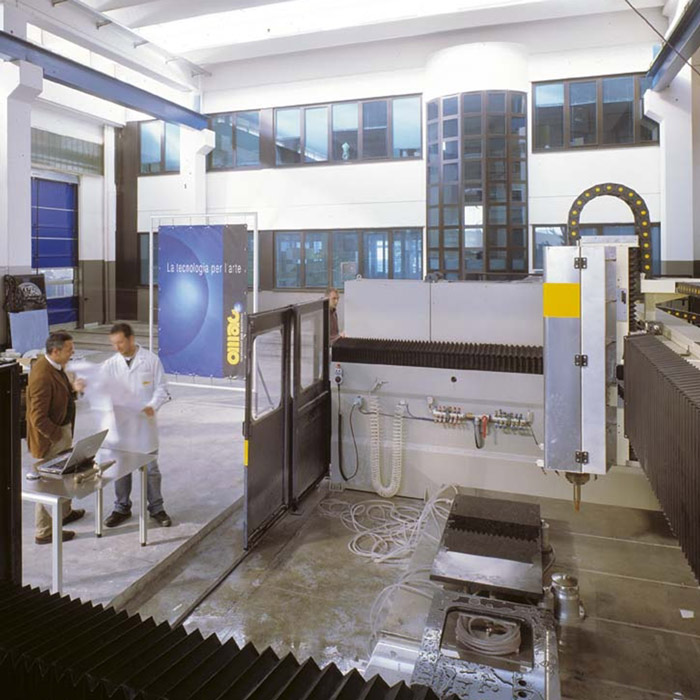

Omag designs, produces and distributes technology,

Our skill lies in manufacturing CNC machines for different industries.

In these 45 years of activity Omag has produced systems intended for the world of natural stone, granite, marble, artificial stone and similar, ceramic, glass, cement and acrylic.

OMAG is an Italian company founded by Cav. Angelo Albani, now in its second generation, present on the machine tool market for over 45 years, leader in the production of large customizable machining centres, appreciated in all sectors where maximum rigidity, high performance and high precision.

OMAG does not limit itself to designing and building its own machines, but has concentrated group companies in its production area, with specific skills (carpentry, mechanical processing, software and research), in synergy with each other, in order to guarantee global control of quality.

Cutting, shaping, polishing, engraving, sculpture, these are the functions required of a numerically controlled machining center and OMAG is able to fully satisfy its customers’ expectations. Systems and methods of loading and unloading the pieces to be machined today are crucial and necessary phases for calculating the productivity of a plant.

A great effort has been made in developing a human/machine interface, so called (HMI), which is flexible, fast, safe to use and modern. All this is now essential to integrate our systems with the parameters required by “industry 4.0 and 5.0”.

Providing solutions is what we have always done and what we intend to continue doing, integrating our products and services with the most innovative solutions on the world market.

In designing its systems, Omag knows exactly the expectations of its customers, OMAG has always thought that efficiency is doing things well and that effectiveness is doing the right things.

The training service is one of our strong points. We believe that training our clients is one of the fundamental pillars for professional and personal success.

Training is an important tool, as it allows you to acquire new knowledge and skills that can be used to improve and achieve your goals